Description

100% engineered and fabricated in house by Pinnacle Stainless in Denver, CO

Automated filling, chilling, and discharge to the attached extraction skid

C1D2 rated

Closed-loop system for safe operation

Continuous -40°C solvent delivered at 60 gallons per hour

Gives the option to upgrade AES system to in-line chilling

Reduces the overall usage of ethanol

Third-party engineer peer-reviewed

UL listed hazardous location control panel

200-Gallon Insulated Clean Solvent Storage

90-Gallon Jacketed and Insulated Solution Holding Tank

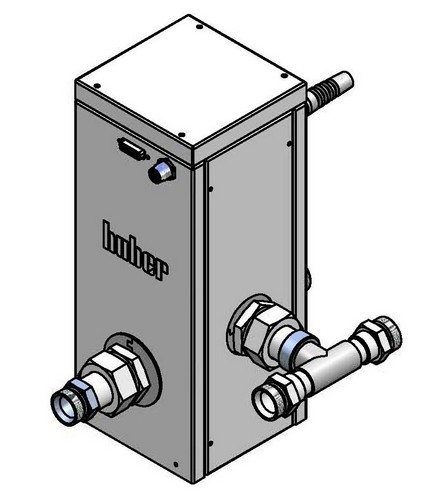

Pneumatic Control Valves

Liquid Level Sensor

Temperature Monitoring Controls

Pinnacle Stainless Custom Heat Exchanger

Liquid Drive Pump with Custom seals

Dimensions: 96″ x 48″ x 98″

Weight: 2400lbs (including crating)