Description

Model:

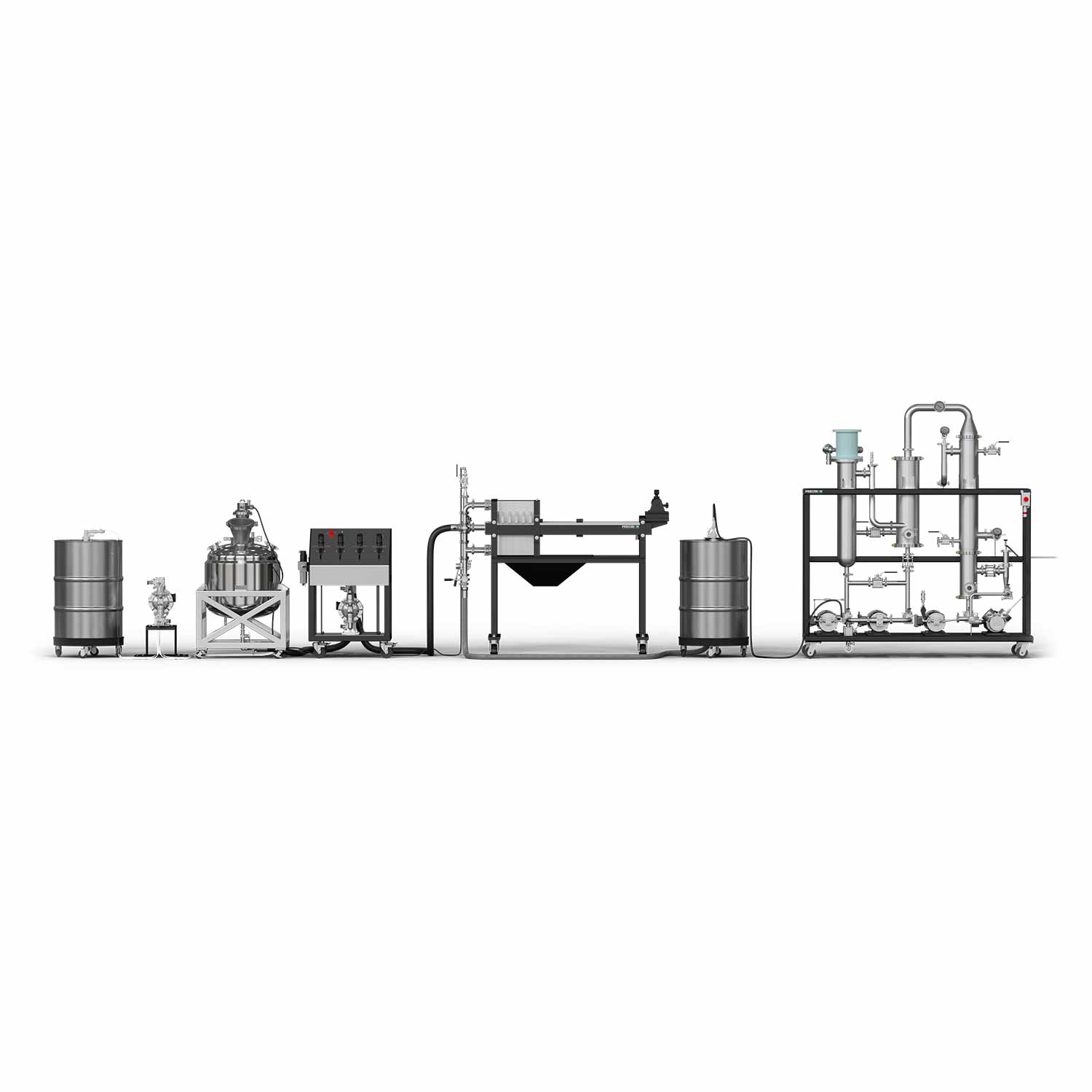

L-SEP Model 60LPH

Dimensions (approx.):

120” x 32” W x 49”

Weight (approx.):

1250 lbs

Throughput:

60L of crude per hour

Interior Finish Spec:

Ra 32 or better

Vessel Sizes:

1 QTY 100L (feed)

2 QTY 255L (receiving)

Linesets:

UG-21 compliant PTFE

Mixer Air Requirements:

78 CFM @ 100 PSI

Maximum Working Volume:

610 Liters

Install & Training:

2 days depending on operator’s needs

Extremely low operational cost (approx. $0.50 per liter)

High throughput batch process

97% removal of lipids from crude oil

GRAS, instrument grade solvents

Installation, equipment, and support included in price

Up to 60L per hour of crude oil processing in standard configuration

Scalable technology with bulk configurations available

Ultrafine 3-micron filtration

Process is electrical free, only requires nitrogen and compressed air

Approximate cycle time of 8-10 minutes per 100L batch

Works with hydrocarbon or CO2 extracts, removes lipids, fats, and waxes from crude oil

Recommended C1D2 process

Solvent evaporation can be sized to any throughput from 10-300L per hour

RV100 Reactor w/ mixer and temperature monitor

FP1 Filter Press

All hosing and connections

2x 255L holding tanks

Nitrogen hose adapter

Model:

L-SEP Model 60LPH

Dimensions (approx.):

120” x 32” W x 49”

Weight (approx.):

1250 lbs

Throughput:

60L of crude per hour

Interior Finish Spec:

Ra 32 or better

Vessel Sizes:

1 QTY 100L (feed)

2 QTY 255L (receiving)

Linesets:

UG-21 compliant PTFE

Mixer Air Requirements:

78 CFM @ 100 PSI

Maximum Working Volume:

610 Liters

Install & Training:

2 days depending on operator’s needs