Description

PARAMETER

VALUE

PARAMETER

VALUE

Feed Rate

400L / 1hr

Max Temp Crude OIl

25-45C

Feed Compositions: Alcohol

96.5%

Steam Pressure

12-24 PSI

> 99.9%

Feed Compositions: Oil

3.5%

Cooling Water Temp.

7C

Alcohol Recovery Rate

400 LPH

Distillate Composition:Alcohol

>99.9%

100% engineered and fabricated in house by Pinnacle Stainless in Denver, CO

100L/hr solvent recovery rate

35 kW steam generator and 25 kW chiller at 40°F required for operation

Closed-loop system designed for safe operation

Equipment built to food and sanitary standards

Rising film technology for minimal degradation

Third-party engineer peer-reviewed

Touch screen operation

UL hazardous location controls

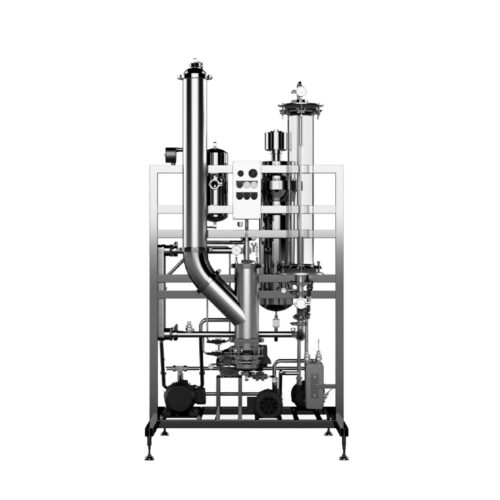

Pinnacle Stainless SRS Evaporator Skid

Pinnacle Stainless C1D2 UL Listed & Approved Electronics

Training and Install Support

System Dimensions (L x W x H in.): 98″ x 40″ x 95″

System Weight: 2400 lbs (including crating)

Closed-loop system designed for safe operation

400L/hr solvent recovery rate

Rising film technology for minimal degradation

Equipment built to food sanitary standards

Touch Screen operation

UL hazardous location controls

Third-party engineer peer-reviewed

100% engineered and fabricated in house by Pinnacle Stainless in Denver, CO

140 kW steam generator and 100 kW chiller at 40°F required for operation

Pinnacle Stainless SRS Evaporator Skid

Pinnacle Stainless C1D2 UL Listed & Approved Electronics

Training and Install Support

System Dimensions (L x W x H in.): 114.25″ x 43.5″ x 98.25″

System Weight: 2400 lbs (including crating)