Description

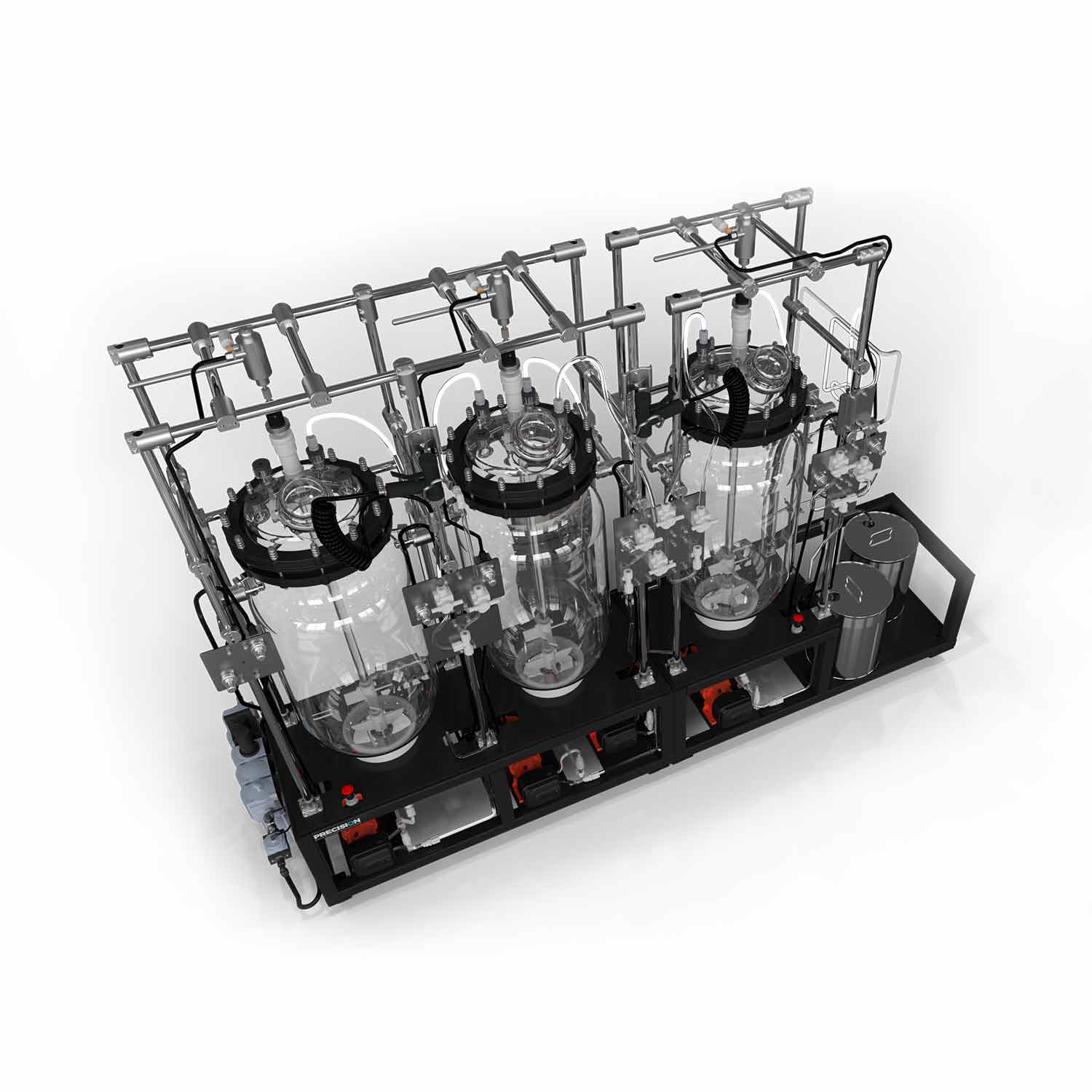

Dimensions (approx.):

120” L x 32” W x 49” H

Weight (approx.):

1450 lbs.

Throughput:

7L of crude per hour

Interior Finish Spec:

Glass

Vessel Sizes:

3x 100L

Linesets:

UG-21 Compliant PTFE

Minimum Operational Temperature:

-40°C

Maximum Working Volume:

9.8 FT3 (284 Liters)

Install & Training:

Up to 3 Days

Total Electrical:

230V, 17.3 Amps, 756W (3.3 amps 14 amps from Huber)

Pumps (3x):

230V, 40W, 1 Phase

110-115V, 20W, 1 Phase

Reactors (3x):

110V 60Hz, 1 Phase, 250W

230V 50/60Hz, 1 Phase, 250W

CC-308B (TCU):

230V 50/60Hz, 1 Phase, 14 amps

99 % removal of THC/THC-A cannabinoids from hemp crude oil.

99 % solvent recovery rate from the process

Extremely low operational costs (approx. $3.50 per liter)

GRAS, instrument grade solvents

Installation, equipment, license, and support included in price

Non-hazardous waste streams

No-cross contamination of THC/THC-A into output streams

Semi-continuous process

Up to 7L per hour of crude oil remediation in standard configuration

3x 100L Reactors (ACE Glass) with mixer and temperature monitor

3x Watson Marlow Peristaltic Pump

Huber CC308B (Holds jacket @ 25°C)

3x Tubes

3x Sanitary 3-way ball valves

3x Glass holding vessels

Dimensions (approx.):

120” L x 32” W x 49” H

Weight (approx.):

1450 lbs.

Throughput:

7L of crude per hour

Interior Finish Spec:

Glass

Vessel Sizes:

3x 100L

Linesets:

UG-21 Compliant PTFE

Minimum Operational Temperature:

-40°C

Maximum Working Volume:

9.8 FT3 (284 Liters)

Install & Training:

Up to 3 Days

Total Electrical:

230V, 17.3 Amps, 756W (3.3 amps 14 amps from Huber)

Pumps (3x):

230V, 40W, 1 Phase

110-115V, 20W, 1 Phase

Reactors (3x):

110V 60Hz, 1 Phase, 250W

230V 50/60Hz, 1 Phase, 250W

CC-308B (TCU):

230V 50/60Hz, 1 Phase, 14 amps