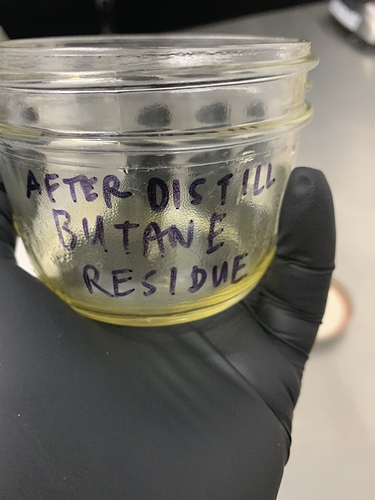

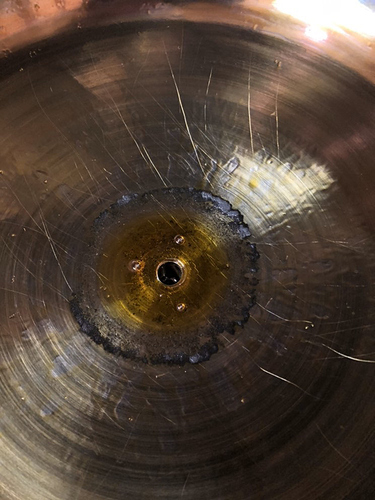

Mystery Oils? Always pre-distill your hydrocarbon solvents, and use a reputable supplier that decontaminates tank internals, if you’re in Canada, we’re here to help you!

It’s frightening to think what industrial suppliers have led our industry to believe is “safe” or “instrument grade” for extraction. Whether or not you have trace elements in your final product, you’ve exposed the product, your lab, your team and your equipment to cancer causing contaminate and toxic waste accumulations. Benzene accumulations cause cancer and reproductive harm.

In most industries these standards are enforced by federal and international agencies and guidelines: AMS, FDA, FSA, GMP, ISO just to name a few.

Ask yourself a very simple question: Would you drink coffee from a restaurant that shows you a COA for their “clean coffee” even if they are serving it in a filthy mug used by 1000’s of other customers with years of sediment accumulating at the bottom without ever being cleaned between use?

Is the coffee still clean?

Industrial suppliers don’t get it because it’s more profitable to sell “clean gas” in “dirty mugs” than to take the time or expense required for cleaning LPG. Most industrial suppliers don’t even have the equipment to clean. Your average industrial gas supplier has been selling LPG in dirty tanks for 50+ years because when you run it to your stove, hot water tank or furnace you are burning off the cancer causing contaminates.

This is just not the case in our application and to think you still have “clean coffee” when you continually fill into a dirty mug is a farce. Mystery oil is generally the accumulation of toxic and cancerous waste and sediment from manufacturing lubricants to benzene accumulations that collect in the bottom of industrial cylinders.

If you serve instrument grade gas in a cylinder that is cleaned before every refill, you won’t have mystery oil. Just like a restaurant that cleans the dishes between customers.

Our tanks are decontaminated with our patented process before EVERY refill by certified hazmat handlers that are also checking for leaks, tank damage, compromised valves and more. This process involves a Triple Phase Decontamination Cleaning™ and with this process we provide Certificates of Decontamination for the cylinder that combined with the Certificate of Analysis on the gas can give you the peace of mind that you’re doing what’s right for consumers, your employees, yourself and our industry as a whole.

Our business was built on setting higher standards even when the government isn’t yet regulating. We were involved with several solvent companies before forming Solvent Direct and each of those companies chose profits over purity and people. Solvent Direct was created to deliver product Engineered for Extraction™ to our industry with the convenience of delivery you can’t find anywhere else in the US because Purity is Our Priority.

Today we have 9 hubs across the US and a fulfillment centers in Canada, Colombia and South Africa. With fleet vehicles running same-day deliveries in most mature markets and partner carriers handling last mile delivery worldwide, no one in the industry can deliver your gas, ethanol, filtration media, dry ice and more on time, every time. We even ship certain quantities via Fedex worldwide.

We are currently working with Federal and State officials to bring this compliance gap into the light. To learn more visit solvendirect.com/

See Cleaning process here: https://www.youtube.com/watch?v=29TcEt4_xZA 4

Original article written by: Lex @ SolventDirect.com