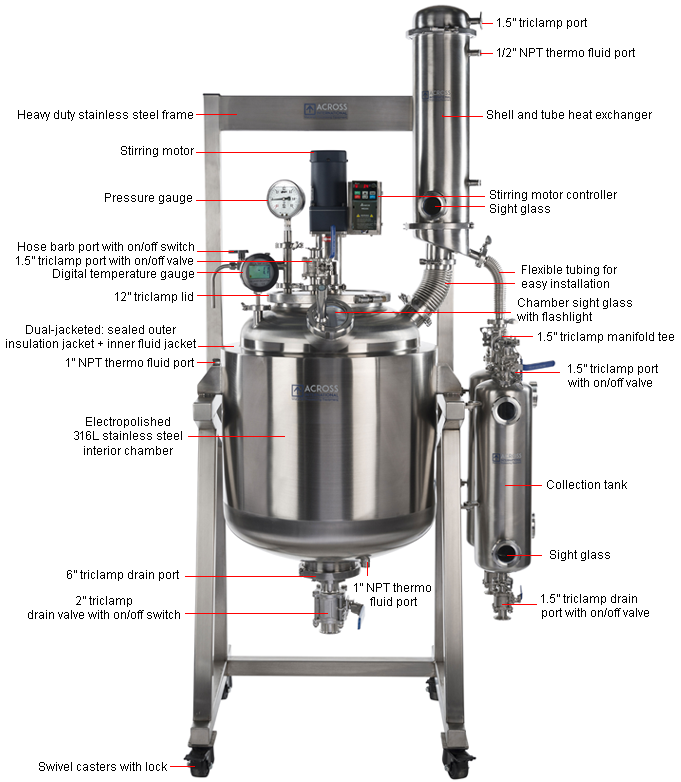

Description

Model

SR100

Electric stirring motor

220V, 50/60Hz, 1~Phase, 200 watts, 1/4 HP Rotation: 450 rpm max. (±8%) Starting torque: 3.0 N.m Rated toruqe: 1.54 N.m Built-in gearbox ratio: 3:1 to 180:1 Controller: Delta, UL listed

Pneumatic stirring motor

– Power: 1/4 HP – Rotation: 450 rpm max. (±8%) – Compressed air pressure range: 30 to 80 psi (0.2 to 0.55 MPa) – Working temperature: -10C to 70C – For constant use: set rpm to 80% of maximum rpm – Motor lubricant

Daphne Eponex EP-No. 1

Check/replenish/replace every 500 hours

– Air lubricant

Type: JIS K2213-1 (ISOVG32)

Recommended products: Shell Vitrea Oil 32, JOMO Turbine 32, COSMO Turbine 32

Speed: 2-3 drops per minute

– For safety purpose, detach compressed air supply when not in use, left un-attended or at night – Do not run motor un-loaded – Set Air Adjuster to minimum at initial run, make sure motor is working properly, before increasing CFM – Before inspecting unit, stop the motor and detach air supply. Do NOT inspect unit when motor is in action. – Make sure exhaust port/hole is clear from any debris or blockage – Check every 2-3 days: Air Lubricant, Air Filter water drain

Port configuration

Lid: 6″ triclamp Center motor port: 3″ triclamp Drain port: 6″ triclamp Drain port on/off valve: 2″ triclamp Vacuum port: 1.5″ triclamp Condenser recirculating fluid port: 1/2″ female NPT Vessel jacket recirculating fluid ports: 1″ female NPT

Main vessel

Volume: 100L Minimum fill volume: 25L Material: 316L grade stainless steel Interior finish: ElectroPolished

Agitator

Structure: propeller, 3-blade, dual-layer (standard) Style: quick-change Material: 316L grade stainless steel Detachable length: 20 inches

Center fluid jacket

Volume: 22L Material: 304 grade stainless steel

Outer insulation jacket

Insulation material: perlite, 2″, sealed Housing material: 304 grade stainless steel

Collection tank

10L x 2

Material

All wetted parts 316L grade stainless steel on main reactor body Rest of reactor in 304 grade stainless steel

Main Condenser

Style: shell and tube heat exchanger Number of tubes: 70 Condensing area: 0.89 m2

Pressure

Ultimate vacuum level: 1 Torr Maximum positive pressure (C1D1 peer reviewed to 15 psi)

Main vessel: 70 psi

Fluid jacket: 40 psi

Temperature range

-55°C to 250°C (-67°F to 482°F)

Temperature sensor/display

Regular: BOOST.TTA.0101, -200C to 480C, 50.5 clamp Explosion proof: BOOST.TTA.0102, -200C to 480C, 50.5 clamp

Sealing gasket

Food grade Viton

Main Mounting Frame

Heavy duty 2 x 2″ 304 grade stainless steel, mounted on four casters

Drain port ground clearance

Drain port: 19.5 inches Drain valve: 14 inches

Unit/shipping weight

255 Lbs / 350 Lbs

Unit/shipping dimensions

38 x 32 x 82″ (WxDxH)

Compliance

ETL tested to UL and CSA standards C1D1 peer review by PSI (optional)