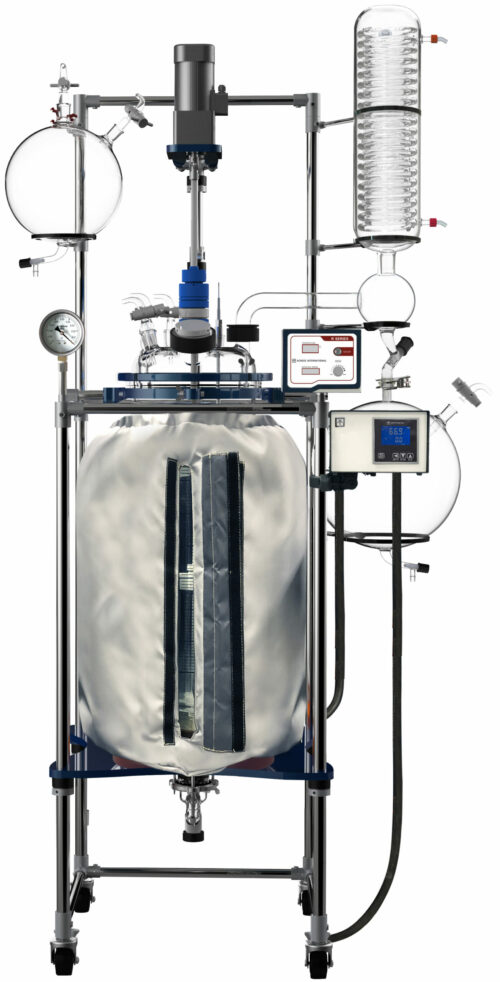

Description

Model

SR200

Electric stirring motor

220V, 50/60Hz, 1~Phase, 200 watts, 1/4 HP Rotation: 450 rpm max. (±8%) Starting torque: 3.0 N.m Rated torque: 1.54 N.m Built-in gearbox ratio: 3:1 to 180:1 Controller: Delta, UL listed

Pneumatic stirring motor

– Power: 1/4 HP – Rotation: 450 rpm max. (±8%) – Compressed air pressure range: 30 to 80 psi (0.2 to 0.55 MPa) – Working temperature: -10C to 70C – For constant use: set rpm to 80% of maximum rpm – Motor lubricant

Daphne Eponex EP-No. 1

Check/replenish/replace every 500 hours

– Air lubricant

Type: JIS K2213-1 (ISOVG32)

Recommended products: Shell Vitrea Oil 32, JOMO Turbine 32, COSMO Turbine 32

Speed: 2-3 drops per minute

– For safety purpose, detach compressed air supply when not in use, left un-attended or at night – Do not run motor un-loaded – Set Air Adjuster to minimum at initial run, make sure motor is working properly, before increasing CFM – Before inspecting unit, stop the motor and detach air supply. Do NOT inspect unit when motor is in action. – Make sure exhaust port/hole is clear from any debris or blockage – Check every 2-3 days: Air Lubricant, Air Filter water drain

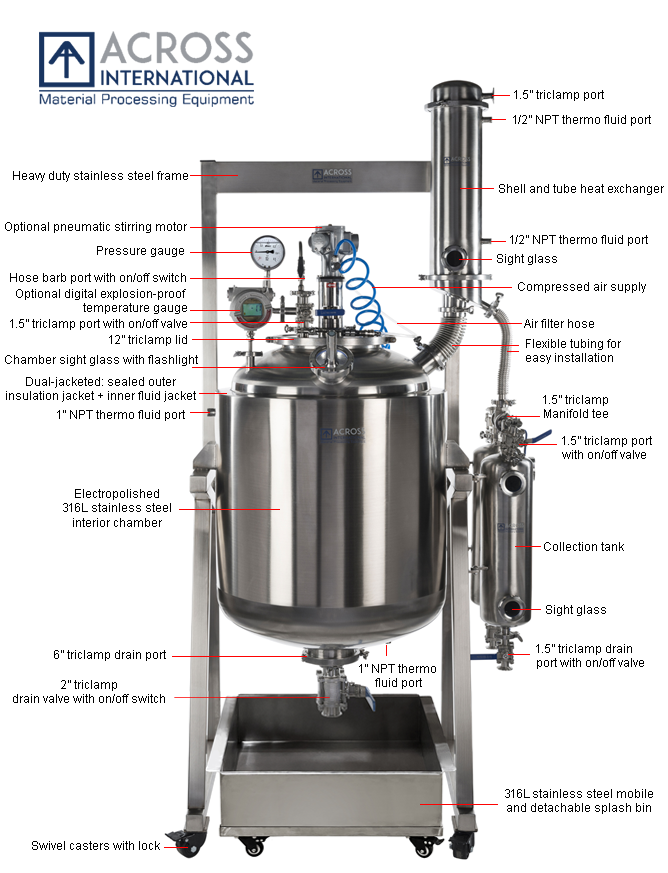

Port configuration

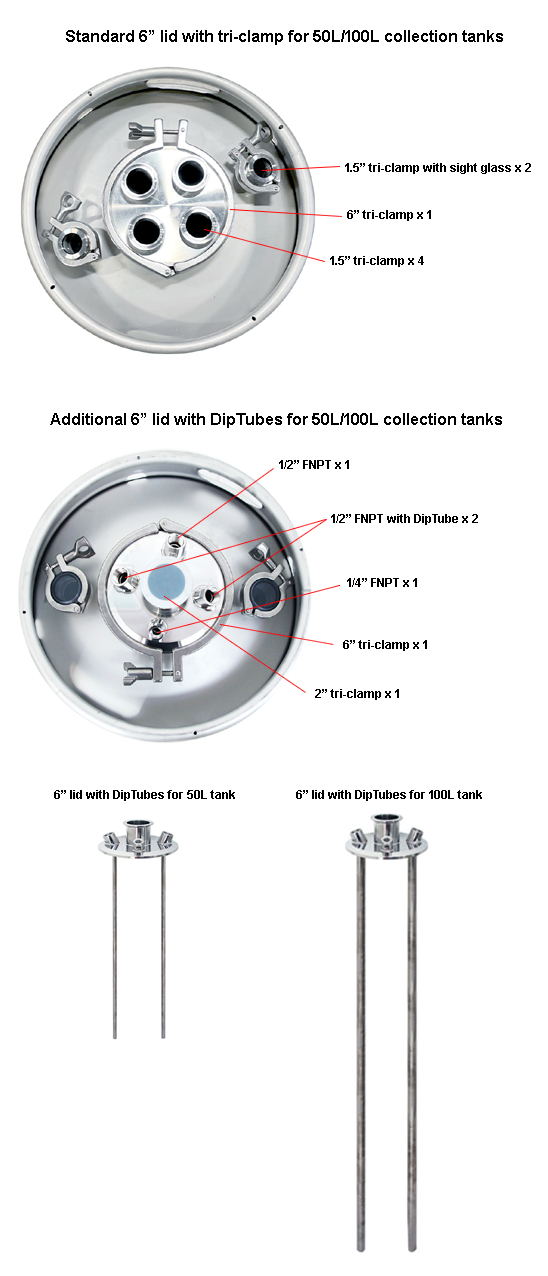

Lid: 6″ triclamp Center motor port: 3″ triclamp Drain port: 6″ triclamp Drain port on/off valve: 2″ triclamp Vacuum port: 1.5″ triclamp Condenser recirculating fluid port: 1/2″ female NPT Vessel jacket recirculating fluid port: 1″ female NPT 50L/100L collection tanks * Standard lid: 6″ tri-clamp, with 1.5″ tri-clamp x 4 * Additional lid: 6″ tri-clamp, with 1/2″ FNPT with DipTube x 2, 1/2″ FNPT x 1, 1/4″ FNPT x 1, 2″ tri-clamp x 1 * Top of tank: 1.5″ tri-clamp with sight glass x 2 * Drain port: 1.5″ tri-clamp x 1

Main vessel

Volume: 200L Minimum fill volume: 40L Material: 316L grade stainless steel Interior finish: ElectroPolished

Agitator

Structure: propeller, 3-blade, dual-layer (standard) Style: quick-change Material: 316L grade stainless steel Detachable length: 28 inches

Center fluid jacket

Volume: 35L Material: 304 grade stainless steel

Outer insulation jacket

Insulation material: perlite, 2″, sealed Housing material: 304 grade stainless steel

Collection tank

Option 1: 10L x 2, 316L stainless steel, with manifold Option 2: 50L x 1, 304 stainless steel, with dolly (15.5″ diameter, 23.5″ height, 30″ with dolly) Option 3: 100L x 1, 304 stainless steel, with dolly (15.5″ diameter, 43″ height, 49.5″ with dolly)

Material

All wetted parts 316L grade stainless steel on main reactor body Rest of reactor in 304 grade stainless steel

Main Condenser

Style: shell and tube heat exchanger Number of tubes: 70 Condensing area: 0.89 m2

Pressure

Ultimate vacuum level: 1 Torr Maximum positive pressure (C1D1 peer reviewed to 15 psi)

Main vessel: 70 psi

Fluid jacket: 40 psi

Temperature range

-55°C to 250°C (-67°F to 482°F)

Temperature sensor/display

Regular: BOOST.TTA.0101, -200C to 480C, 50.5 clamp Explosion proof: BOOST.TTA.0102, -200C to 480C, 50.5 clamp

Sealing gasket

Food grade Viton

Main Mounting Frame

Heavy duty 2 x 2″ 304 grade stainless steel, mounted on four casters

Drain port ground clearance

Drain port: 19.5 inches Drain valve: 14 inches

Unit/shipping weight

570 Lbs / 890 Lbs

Unit/shipping dimensions

43 x 34 x 90″ (WxDxH)

Compliance

ETL tested to UL and CSA standards C1D1 peer review by PSI (optional)