Description

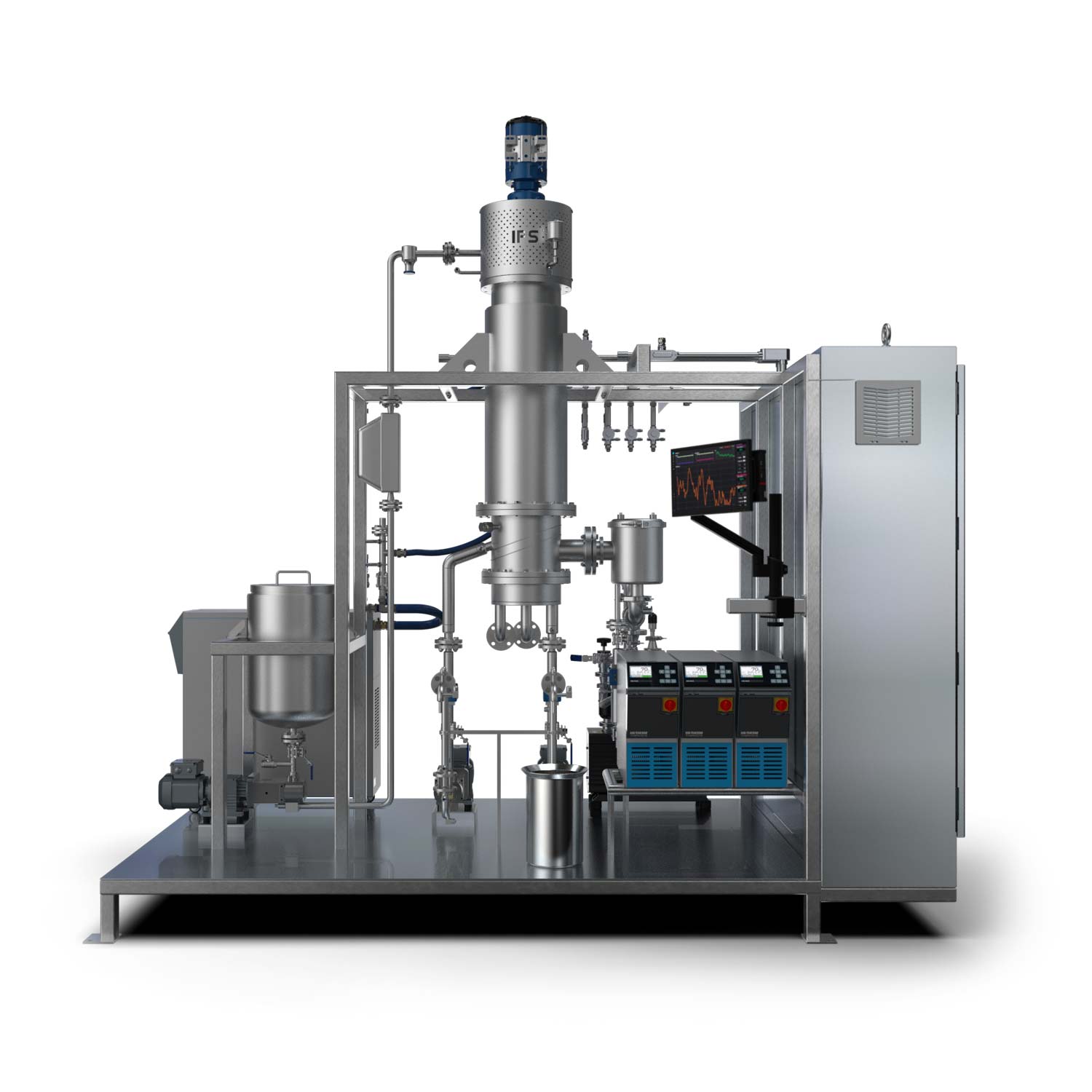

20-50 liters per hour input feed capability (Variable based on feed material)

Common skid frame for all utilities except cold trap chiller

Completely jacketed stainless steel process piping

Digital pressure gauges

Good Manufacturing Practices (GMP) forward design

Inline sight glasses

Insulated cold trap with internal & external coils

Jacketed Coriolis flow meter

Jacketed feed tank, 8-Gallon

Manual isolation valves

Material contact surfaces: 316L stainless steel

Various HMI options*

Various vacuum system options*

Standard PTFE rollers with splash guards for maximum longevity

Short path evaporator with internal, high surface area coil condenser

All chilling & heating fluids

Closed-loop hot oil circulator

Max. 250°C

For evaporator

Max. 250°C

For evaporator

Closed-loop tempered water units (2)

Max 100°C

For feed tank & system jacketing

For internal short path condenser

Max 100°C

For feed tank & system jacketing

For internal short path condenser

Cold trap chiller: -30°C to -50°C (Included)

Closed-loop cold trap chiller: -50°C to -80°C ( $15,000.00)

Max. 250°C

For evaporator

Max 100°C

For feed tank & system jacketing

For internal short path condenser

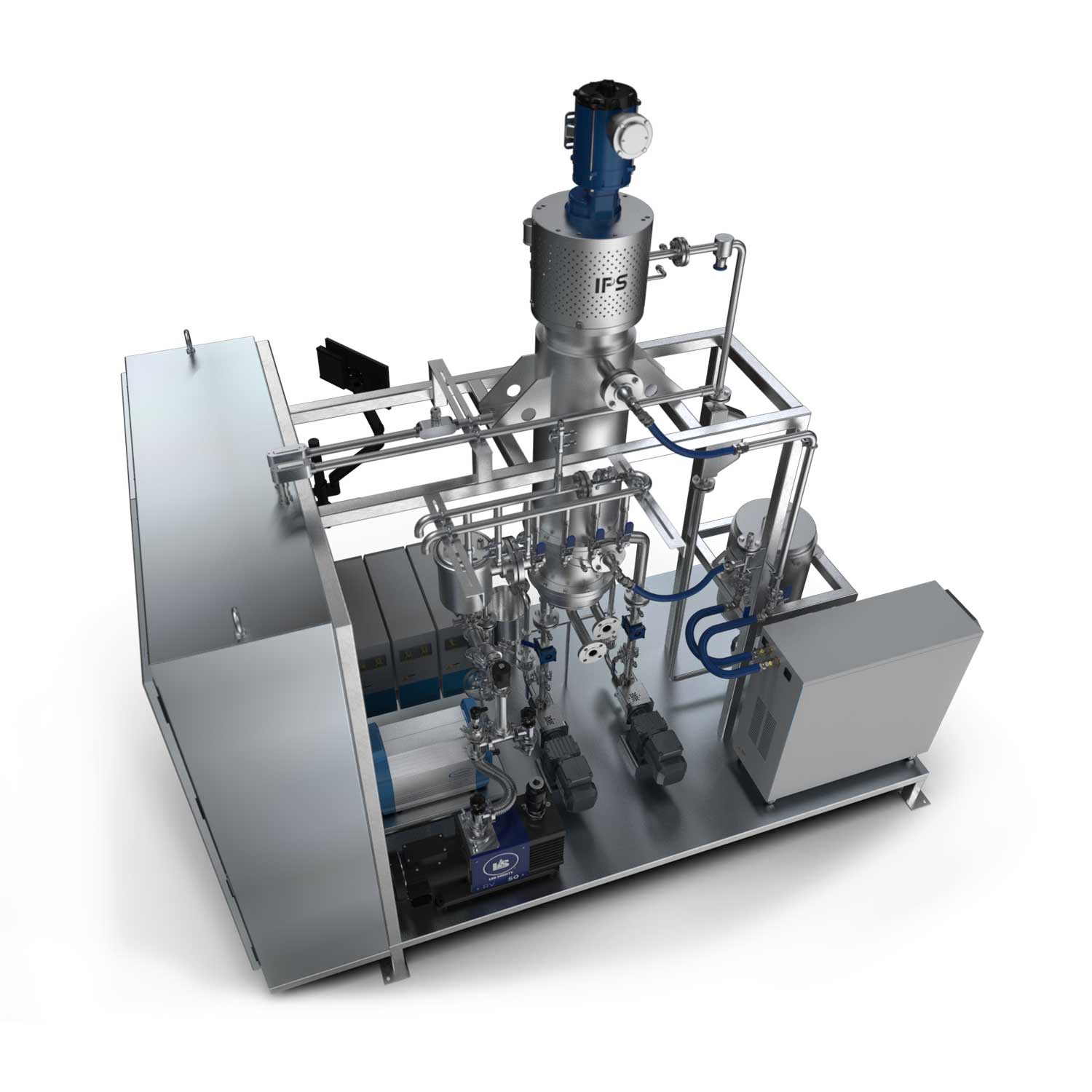

All Vacuum Clamps, Hoses, and Valves

Consistent Bore Size 40-50mm to Pump Inlets

Dual-point Vacuum Monitoring System with Valve Control

Vacuum Pre-Filter and Secondary Catch

Multiple Pump Options*:

High Capacity/High Vacuum Diaphragm Pump

Rotary Vane Pump Oil Mist Filter

Booster Pump Kits

Dry Screw Pumps (coming soon)

High Capacity/High Vacuum Diaphragm Pump

Rotary Vane Pump Oil Mist Filter

Booster Pump Kits

Dry Screw Pumps (coming soon)

High Capacity/High Vacuum Diaphragm Pump

Rotary Vane Pump Oil Mist Filter

Booster Pump Kits

Dry Screw Pumps (coming soon)

Included standard on all units: EliteLab® Core Touchscreen Control Interface

Temperature Control Unit (TCU) consolidated controls

Pressure Control & Measurement

Custom Presets and Automation Settings for “Recipes” and Repeatability

Multi-day data logging of all parameters

Temperature Control Unit (TCU) consolidated controls

Pressure Control & Measurement

Custom Presets and Automation Settings for “Recipes” and Repeatability

Multi-day data logging of all parameters

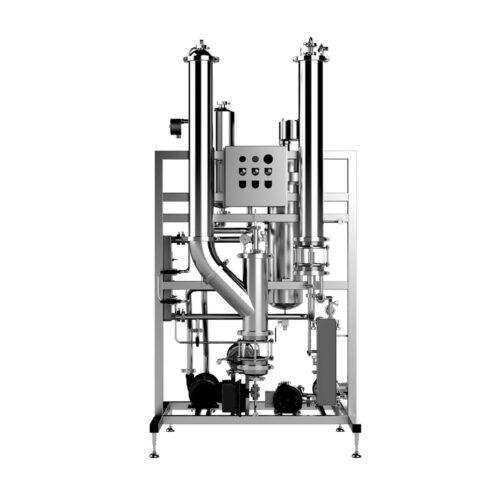

Programmable Logic Controller (PLC) by Allen Bradley (additional fee*)

22” Touchscreen Control Interface integrates all VFDs into a simple-to-use interface for control, data logging, and management of the distillation unit

Preset and custom alarms for over/under pressurization as well as other parameters for production stability

Remote control options through software loaded onto external tablet or PC

22” Touchscreen Control Interface integrates all VFDs into a simple-to-use interface for control, data logging, and management of the distillation unit

Preset and custom alarms for over/under pressurization as well as other parameters for production stability

Remote control options through software loaded onto external tablet or PC

PLC with Automated Level Sensors (additional fee*)

Fluid level sensors are added into process lines to sense the flow rates, which control the speed of respective material pumps

Simply set the flow rate on the feed pump and the sensors will automatically adjust the flow rates for each respective material pump accordingly without user input

Requires additional height*

Fluid level sensors are added into process lines to sense the flow rates, which control the speed of respective material pumps

Simply set the flow rate on the feed pump and the sensors will automatically adjust the flow rates for each respective material pump accordingly without user input

Requires additional height*

Temperature Control Unit (TCU) consolidated controls

Pressure Control & Measurement

Custom Presets and Automation Settings for “Recipes” and Repeatability

Multi-day data logging of all parameters

22” Touchscreen Control Interface integrates all VFDs into a simple-to-use interface for control, data logging, and management of the distillation unit

Preset and custom alarms for over/under pressurization as well as other parameters for production stability

Remote control options through software loaded onto external tablet or PC

Fluid level sensors are added into process lines to sense the flow rates, which control the speed of respective material pumps

Simply set the flow rate on the feed pump and the sensors will automatically adjust the flow rates for each respective material pump accordingly without user input

Requires additional height*

3-Day onsite utilities install & mechanical check, and intensive training

Additional days billed at $3000 per day

Additional days billed at $3000 per day

Full Factory Acceptance Testing (FAT) pre-shipment

Standard Operating Procedures (SOPs)

Clean-in-place (CIP) Procedures

On-going Quarterly Over The Air (QOTA) checkups

Additional days billed at $3000 per day